service

After-Sale Service

Quick response to the client

Highly qualified technicians

Permanent Assistance

Spare parts stock guaranteed

Operación de los equipos

En esta etapa se configurarán los diferentes parámetros necesarios para poder realizar el desbaste de la pieza, tales como los sistemas de referencias, colocación del bloque en bruto o stock, colocación de fresa, etc.

Programación

En esta etapa se plantea el programa de mecanizado en sí, ya que se detallan las estrategias de mecanizado a realizar en función de la pieza deseada y el material a mecanizar.

Dibujo

Se realiza el dibujo en 2D o 3D correspondiente de la pieza deseada.

2D: Autocad – Coreldraw – Illustrator – Solidworks – Inventor

3D: Autocad – Rhino – Solidworks – Inventor – Catia

(entre otros)

Testing Center

and Laboratory

We have a laboratory and testing center where we conduct technological assessments and develop our programs and designs based on practical experiences.

We are equipped with the necessary tools to test each product and simulate work areas or production lines in both practical and virtual formats.

Tests Conducted:

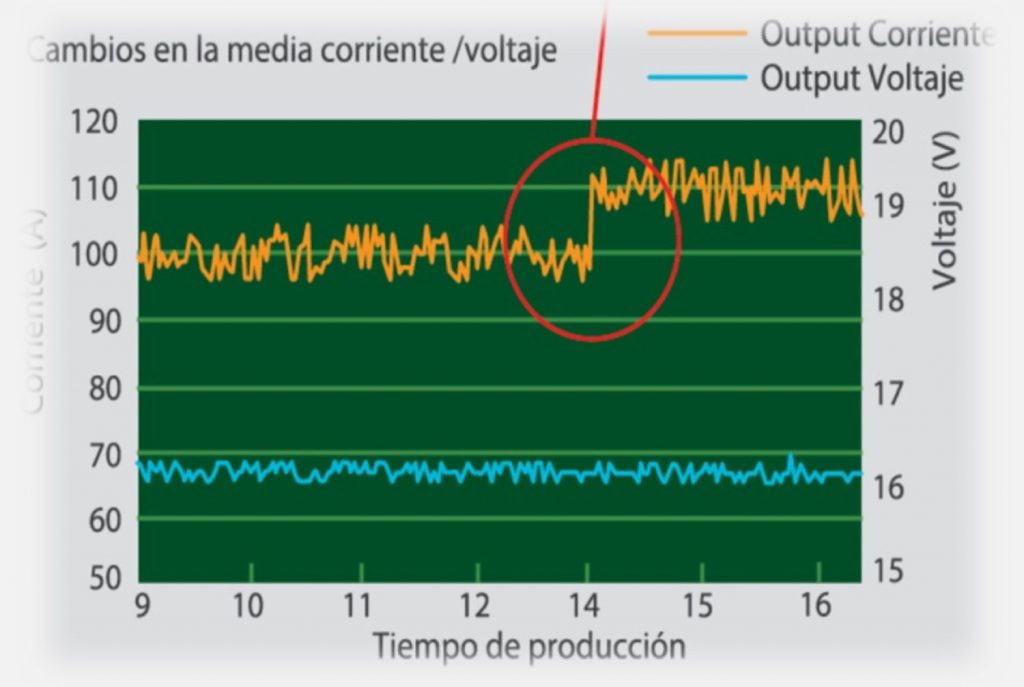

Welding Parameter Settings

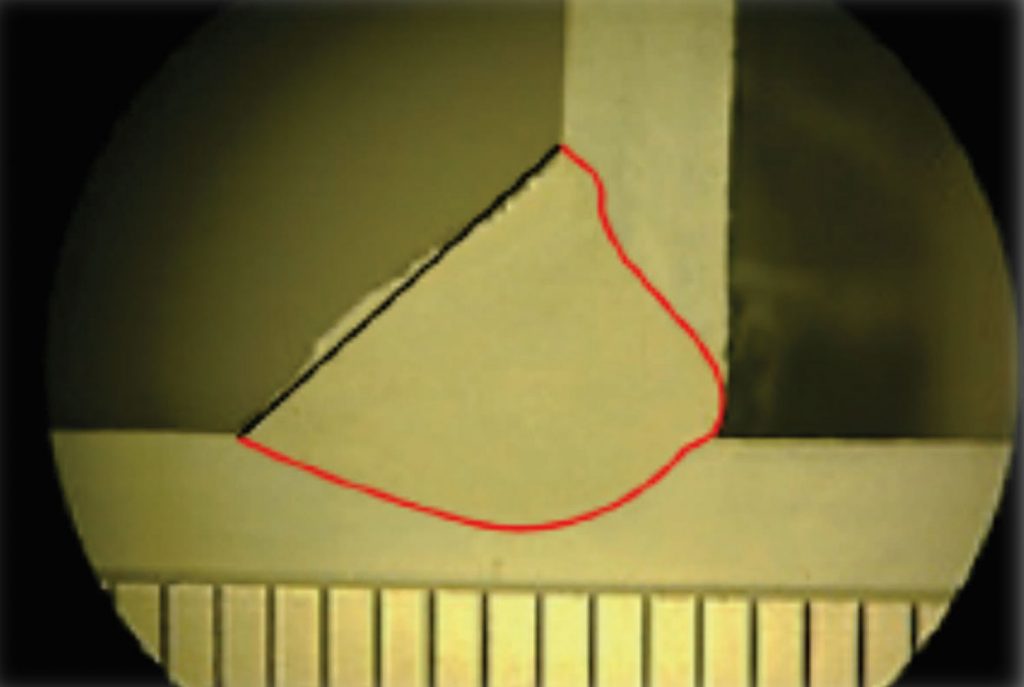

Metallographic Study

Welding Parameter Correction

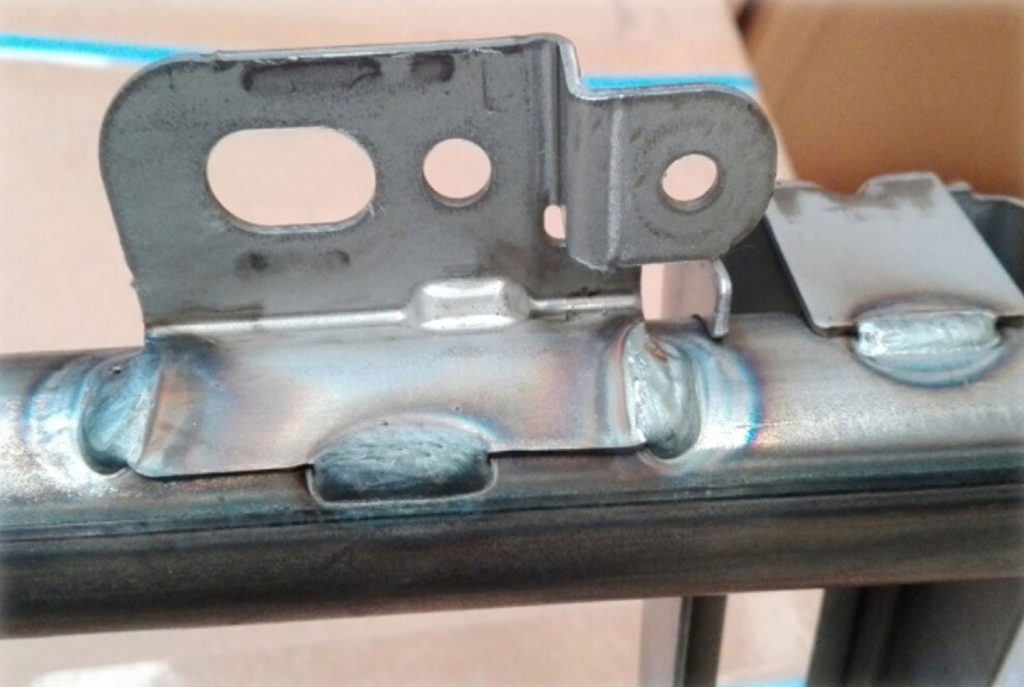

Device Adjusted to Theoretical Zero

Adjustment Based on Measurements

Consumables Studies

Welding with Re-adjusted Fixtures

New Part Analysis

Final Confirmation with Control Gauge